| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Sino-NSH

Model Number : VFD-50

Certification : CE, ISO

Place of Origin : China

MOQ : 1

Payment Terms : T/T, Western Union, L/C

Supply Ability : 30 Per Month

Delivery Time : 15-25 Working Days

Packaging Details : Wooden Case

Color : Blue (Customizable)

Capacity : 1800, 3000, 4000, 6000, 12000, 18000l/h

Power Supply : 380V/50Hz/3P (Customizable)

Dielectric Strength : ≥75kV

Applicable Media : Insulating Oil (Mineral Oil, Synthetic Oil, Vegetable Oil)

Function : Water, Gas, Solids Removal, Dielectric Strength Improvement

Water Removal : ≤5PPM

Gas Removal : ≤0.1%

Filtration Fineness : 1 To 5 μm

Heating Temperature : 20 To 80 ℃ (Adjustable)

Optional Function : Acid, Color, Colloid Removal (Oil Regeneration)

Cofiguration : Luxury Or Standard As Per Your Requirements

High Vacuum Transformer Oil Purifier Insulating Oil Dehydration Degassing Movable

1. Functions

Sino-NSH vacuum oil filter is used to filter the insulating oil in the transformer. It removes moisture, gas, and impurities in the oil efficiently through degassing, dehydration, and precision filtration, and improves the voltage characteristics of the transformer insulating oil.

2. Working Principle

When the oil filter is working, the oil enters the primary filter through the inlet under the action of the internal and external pressure difference, and the large particles of impurities are filtered out. After multi-stage electric heating, the oil enters the special personalized vacuum separator. In the vacuum separator, the surface area of the oil mist is expanded to hundreds of times the original. The water in the oil is quickly vaporized under the conditions of high heat, high vacuum, large surface, and high pumping speed and discharged by the vacuum system.

The water vapor discharged from the upper part of the vacuum separator is first cooled and dehumidified by the condenser and then cooled again in the cooler. The condensed water enters the water storage tank and is discharged. The gas after two condensation and dehumidification is finally discharged into the air by the vacuum pump.

The dry oil after vacuum vaporization and dehydration in the vacuum separator is raised from negative pressure to positive pressure by the oil pump. After fine filtration, the clean oil is discharged from the oil outlet, completing the entire oil purification process.

3. Features

4. Controller & measuring testers

5. Optional Additional Accessories

Online measuring instruments

Others:

6. Parameter

| Parameters | Value | |||||

| VFD-30 | VFD-50 | VFD-75 | VFD-100 | VFD-200 | ||

| Capacity, liters/hour | 1800 | 3000 | 4000 | 6000 | 12000 | |

| Heating Power, kW | 24 | 30 | 48 | 60 | 120 | |

| Total Power, kW | 29 | 36 | 56 | 69 | 132 | |

| Power supply | Fully Customizable | |||||

| Inlet Diameter, mm | 25 | 32 | 40 | 40 | 40 | |

| Outlet Diameter, mm | 25 | 32 | 40 | 40 | 40 | |

| Dimensions | length, mm | 1300 | 1500 | 1500 | 1800 | 2400 |

| width, mm | 900 | 1200 | 1200 | 1400 | 160 | |

| height, mm | 1700 | 1700 | 1800 | 1800 | 1900 | |

| Weight, kg | 600 | 700 | 800 | 900 | 1500 | |

| Processed Oil Spec | Water Content, ppm | ≤5 | ||||

| Dielectric Strength, Kv | ≥75 | |||||

| Filtration Fineness, um | ≤5( or 1-5 as needed ) | |||||

| Gas Content, % | ≤0.1 | |||||

7. What You’ll Get After Your Inquiry

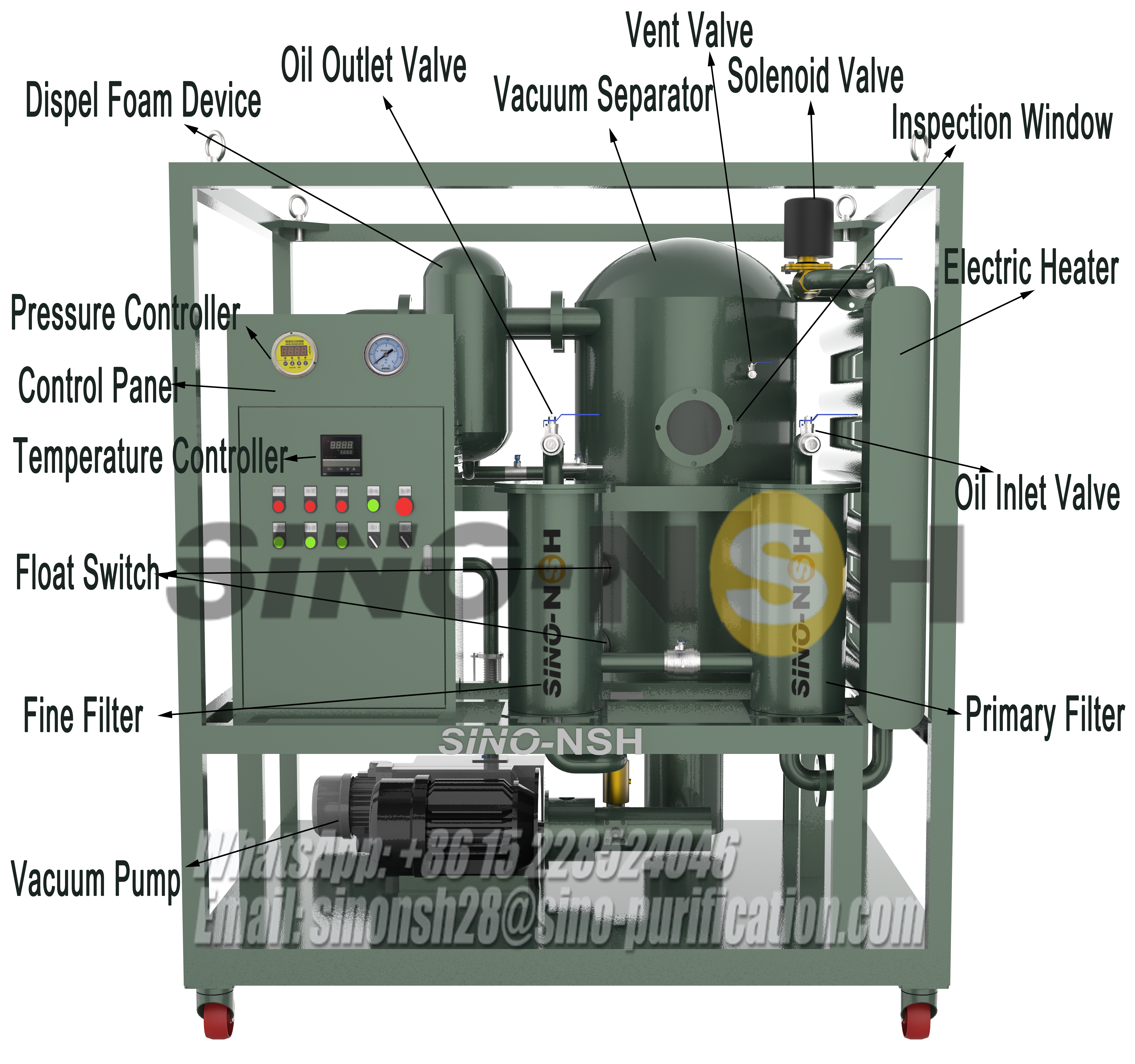

8. Structure Instruction

9. Delivery

10. Pictures

11. Matching Equipment

|

|

High Vacuum Transformer Oil Purifier Insulating Oil Dehydration Degassing Movable Images |